Combined Heat and Power as an Alternative Energy Source

Electricity in the United States is generated, for the most part, from central station power plants at a conversion efficiency of roughly 30 to 35 percent. Meaning for every 100 units of fuel energy in a simple cycle central station electric power plant, we get only 30 to 35 units of electricity. The remainder of the energy in the fuel is lost to the atmosphere in the form of heat.

The thermal requirements of our buildings and facilities are generally provided on-site through the use of a boiler or furnace. The efficiencies of this equipment have improved over the years. Having boilers and furnaces in commercial and industrial facilities with efficiencies of 80 percent and higher is common. Meaning for every 100 units of fuel energy in the boiler/furnace, we get about 80 units of useful thermal energy.

Commercial and industrial facilities that utilize the conventional energy system found in the United States (electricity supplied from the electric grid and thermal energy produced onsite through the use of a boiler/furnace) will oftentimes experience overall fuel efficiencies of between 40 to 55 percent (actual efficiency depends on the facilities heat to power ratio).

Combined Heat and Power (also known as CHP or “cogeneration”) is an integrated system located at or near the building/facility that generates utility-grade electricity which satisfies at least a portion of the electrical load of the facility and captures and recycles the waste heat from the electric generating equipment to provide useful thermal energy to the facility.

CHP implies that heat and electricity are produced simultaneously in one process. The use of combined heat and power helps to improve the overall efficiency of electricity and heat production as these systems combine electricity production technologies with heat recovery equipment. Increasing the conversion efficiency of power generation through CHP helps reduce the environmental impact of power generation. These systems can reach fuel use efficiencies of as high as 75 to 85 percent (versus the conventional energy system at approximately 40 to 55 percent).

A well-designed, installed, and operated CHP system benefits the facility owner (end-user), the electric utility, and society. The high efficiency attained by the CHP system provides the end user with lower overall energy costs, improved electric reliability, improved electric power quality, and improved energy security. In areas where the electric utility distribution grid needs expansion and/or upgrades, CHP systems can provide the electric utility with a means of deferring costly modifications to the grid.

Although the electricity generated on-site by the end-user displaces the electricity purchased from the local electric utility and is seen as lost revenue by many utilities, energy efficiency and lower utility costs are in the best interest of the utility customer and should be considered a reasonable customer option by forward-looking customer oriented utilities. Finally, society, in general, benefits from the high efficiencies realized by CHP systems. The high efficiencies translate to fewer air pollutants (lower greenhouse gas and NOx emissions) than those produced from central station electric power plants.

Hydrogen and Electricity as Alternative Fuels

Since the early 20th Century, oil and the internal combustion engine have dominated transportation. The fortunes of oil and vehicles have been intertwined, with oil racing to meet the energy demands of the ever-growing power and number of personal vehicles, vehicles driving farther in response to growing interstate highway opportunities for long-distance personal travel and freight shipping, and greater personal mobility producing living patterns in far-flung suburbs that require oil and cars to function. In recent and future years, the greatest transportation growth will be in developing countries where the need and the transportation market are growing rapidly. China has an emerging middle class larger than the entire population of the United States, a sign that developing countries will soon direct or strongly influence the emergence of new technologies designed to serve their needs. Beyond deploying new technologies, developing countries have a potentially large second advantage: they need not follow the same development path through outdated intermediate technologies taken by the developed world. Leapfrogging directly to the most advanced technologies avoids legacy infrastructures and long turnover times, allowing innovation and deployment on an accelerated scale. The internal combustion engine and the vehicles it powers have made enormous engineering strides in the past half century, increasing efficiency, durability, and comfort and adding such now-standard features as air conditioning, cruise control, hands-free cell phone use, and global positioning systems. Simultaneously, the automobile industry has become global, dramatically increasing competition, consumer choice, and marketing reach. The most recent trend in transportation is dramatic swings in the price of oil, the lifeblood of traditional vehicles powered by internal combustion engines.

Hydrogen as an Alternative Fuel

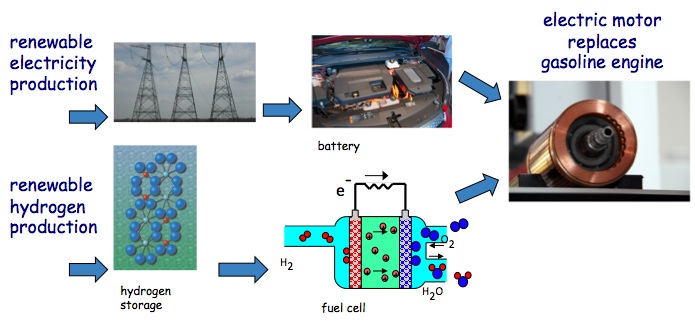

The traditional synergy of oil with automobiles may now show signs of strain. The reliance of vehicles on one fuel whose price shows strong fluctuations and whose future course is ultimately unsustainable presents long-term business challenges. Motivated by these business and sustainability concerns, the automobile industry gradually diversified to other fuels. Hydrogen made its debut in the early 2000s and showed that it has the potential to power vehicles using fuel cells to produce on-board electricity for electric motors (Eberle and von Helmholt, 2010, Crabtree, Dresselhaus, & Buchanan, 2004). One advantage of hydrogen is efficiency, up to 50 percent or greater for fuel cells, and up to 90 percent or greater for electric motors powering the car, compared with 25 percent efficiency for an internal combustion engine. A second advantage is reduced dependence on foreign oil – hydrogen can be produced from natural gas or entirely renewable resources such as solar decomposition of water. A third potential advantage of hydrogen is environmental –the emissions from the hydrogen car are harmless: water and a small amount of heat, though the emissions from the hydrogen production chain may significantly offset this advantage. The vision of hydrogen cars powered by fuel cells remains strong. It must overcome significant challenges, however, before becoming practical, such as storing hydrogen on board vehicles at high densities, finding inexpensive and earth-abundant catalysts to promote the reduction of oxygen to water in fuel cells, and producing enough hydrogen from renewable sources such as solar-driven water splitting to fuel the automobile industry (Crabtree & Dresselhaus, 2008). The hydrogen and electric energy chains for automobiles are illustrated in Figure 1. Many scientists and automobile companies are exploring hydrogen as a long-term alternative to oil.

Electricity as an Alternative Fuel

Electric cars represent a second alternative to oil for transportation, with many similarities to hydrogen (see Figure Electric Transportation). Electric vehicles are run by an electric motor, as in a fuel cell car, up to four times as efficient as a gasoline engine. The electric motor is far simpler than a gasoline engine, having only one moving part, a shaft rotating inside a stationary housing and surrounded by a coil of copper wire. Electricity comes from a battery, whose storage capacity, like that of hydrogen materials, is too small to enable long-distance driving. Developing higher energy-density vehicle batteries is a major challenge for the electric car industry. The battery must be charged before driving, which can be done from the grid using excess capacity available at night, or during the day from special solar charging stations that do not add additional load to the grid. Because charging typically takes hours, a potentially attractive alternative is switching the battery out in minutes for a freshly charged one at special swapping stations. A large fleet of electric cars in the United States would require significant additional electricity, as much as 130 GW, if the entire passenger and light truck fleet were converted to electricity, or 30 percent of average United States electricity usage in 2008. The energy usage of electric cars is about a factor of four less than for gasoline cars, consistent with the higher efficiency of electric motors over internal combustion engines. Although gasoline cars vary significantly in energy efficiency, a “typical” middle-of-the-road value for a five-passenger car is 80kWh/100km. A typical electric car (such as the Think Ox from Norway, the Chevy Volt operating in its electric mode, or the Nissan Leaf) uses ~ 20kWh/100km. While the energy cost of electric cars at the point of use is significantly less, one must consider the cost at the point of production, the electricity generating plant. If the vehicle’s electricity comes from coal with a conversion efficiency of 33 percent, the primary energy cost is 60 kWh/100km, approaching but still smaller than the gasoline car. If combined cycle natural gas turbines generate electricity with 60 percent efficiency, the primary energy cost is 33 kWh/100km, less than half the primary energy cost for gasoline cars. These comparisons are presented in the Table below.

| Gasoline Engine 5 passenger car | Battery Electric Nissan Leaf, Chevy Volt (battery mode), Think Ox | |

| Energy use at point of use | 80 kWh/100km | 20 kWh/100km |

| Energy use at point of production: Coal at 33% efficiency | 60 kWh/100km | |

| Combined Cycle Natural Gas at 60% efficiency | 33 kWh/100km |

| Gasoline Engine 5 passenger car |

Battery Electric Nissan Leaf, Chevy Volt (battery mode), Think Ox |

|

| CO2 Emissions at point of use | 41 lbs | ~ 0 |

| CO2 Emissions at point of production Coal@2.1 lb CO2/kWh |

42 lbs | |

| Gas@1.3 lb CO2/kWh | 25 lbs | |

| Nuclear, hydro, wind or solar | < 1 lb |

The carbon footprint of electric cars requires a similar calculation. For coal-fired electricity producing 2.1 lb CO /kWh, driving 100km produces 42 lbs (19 kgs) of carbon dioxide; for gasfired electricity producing 1.3 lb CO /kWh, 100km of driving produces 26 lbs (11.7 kgs) of carbon dioxide. If electricity is produced by nuclear or renewable energy such as wind, solar or hydroelectric, no carbon dioxide is produced. For a “typical” gasoline car, 100km of driving produces 41 lbs (18.5 kgs) of carbon dioxide. Thus the carbon footprint of a “typical” electric car is, at worst equal, to that of a gasoline car and, at best, zero. Table Comparisons of Carbon Emissions summarizes the carbon footprint comparisons.

The Hybrid Solutions

Unlike electric cars, hybrid vehicles rely only on gasoline for their power. Hybrids do, however, have a supplemental electric motor and drive system that operates only when the gasoline engine performance is weak or needs a boost: on starting from a stop, passing, or climbing hills. Conventional gasoline cars have only a single engine that must propel the car under all conditions; it must, therefore, be sized to the largest task. Under normal driving conditions, the engine is larger and less efficient than it needs to be. The hybrid solves this dilemma by providing two drive trains, a gasoline engine for normal driving, and an electric motor for high power needs when starting, climbing hills, and passing. The engine and motor are tailored to their respective tasks, enabling each to be designed for maximum efficiency. As the electric motor is overall much more efficient, its use can raise fuel economy significantly.

The battery in hybrid cars has two functions: it drives the electric motor and also collects electrical energy from regenerative braking, converted from kinetic energy at the wheels by mall generators. Regenerative braking is effective in start-stop driving, increasing efficiency by up to 20 percent. Unlike gasoline engines, electric motors use no energy while standing still; hybrids, therefore, shut off the gasoline engine when the car comes to a stop to save the idling energy. Gasoline engines are notoriously inefficient at low speeds (hence the need for low gear ratios), so the electric motor accelerates the hybrid to ~15 mph (24 kph) before the gasoline engine restarts. Shutting the gasoline engine off while stopped

increases efficiency by as much as 17 percent. The energy-saving features of hybrids typically lower their energy requirements from 80 kWh/100km to 50-60 kWh/100km, a significant savings. However, it is important to note that despite a supplementary electric motor drive

system, all of a hybrid’s energy comes from gasoline and none from the electricity grid.

The plug-in hybrid differs from conventional hybrids in tapping both gasoline and the electricity grid for its energy. Most plug-in hybrids are designed to run on electricity first and on gasoline second; the gasoline engine kicks in only when the battery runs out. The plugin hybrid is thus an electric car with a supplemental gasoline engine, the opposite of the conventional hybrid cars described above. The value of the plug-in hybrid is that it solves the “driving range anxiety” of the consumer: there are no worries about getting home safely from a trip that turns out to be longer than expected. The disadvantage of the plug-in hybrid is the additional supplemental gasoline engine technology, which adds cost and complexity to the automobile.

The Battery Challenge

To achieve reasonable driving range, electric cars and plug-in hybrids need large batteries, one of their greatest design challenges and a potentially significant consumer barrier to widespread sales. Even with the largest practical batteries, the driving range on electricity is limited, perhaps to ~100km. Designing higher energy density batteries is currently a major focus of energy research, with advances in Li-ion battery technology expected to bring significant improvements. The second potential barrier to public acceptance of electric vehicles is charging time, up to eight hours, from a standard household outlet. This may suit overnight charging at home but could be a problem for trips beyond the battery’s range with a gasoline car; the driver fills up in a few minutes and is on his way. Novel infrastructure solutions, such as battery-swapping stations for long trips, are under consideration.

Comparing gasoline, electric, hybrid, and plug-in hybrid cars is interesting from a sustainability perspective. Hybrid cars take all their energy from gasoline, representing the least difference from gasoline cars. Their supplementary electric drive systems reduce gasoline usage by 30-40 percent, thus promoting the conservation of a finite resource and reducing reliance on foreign oil. Electric cars, however, get all of their energy from grid electricity, a domestic energy source, completely eliminating reliance on foreign oil and the use of finite oil resources. Their sustainability value is, therefore, higher than hybrids. Plug-in hybrids have the same potential as all-electric vehicles, provided their gasoline engines are used sparingly. Regarding carbon emissions, the sustainability value of electric vehicles depends entirely on the electricity source: neutral for coal, positive for gas, and highly positive for nuclear or renewable hydro, wind, or solar. From an energy perspective, electric cars use a factor of four less energy than gasoline cars at the point of use. Still, this advantage is partially compromised by inefficiencies at the point of electricity generation. Even inefficient coal-fired electricity leaves an advantage for electric cars, and efficient gas-fired combined cycle electricity leaves electric cars more than a factor of two more energy efficient than gasoline cars.

Electricity Grid and Sustainability Challenges

Over the past century and a half, electricity has emerged as a popular and versatile energy carrier. Today, electricity is exploited not only for its diverse end uses, such as lighting, motion, refrigeration, communication, and computation but also as a primary energy carrier. Electricity is one of two backbones of the modern energy system (liquid transportation fuels are the other), carrying high-density energy over short and long

distances for diverse uses. In 2009, electricity consumed the largest share of the United States’ primary energy, 38 percent, with transportation a close second at 37 percent. These two sectors also accounted for the largest shares of U.S. carbon emissions, 38 percent for electricity and 33 percent for transportation.

By far, most electricity is generated by the combustion of fossil fuels to turn steam or gas turbines. This is the least efficient step in the energy chain, converting only 36 percent of the chemical energy in the fuel to electric energy when averaged over the present gas and coal generation mix. It also produces all the carbon emissions of the electricity chain. Beyond production, electricity is a remarkably clean and efficient carrier. Conversion from the rotary motion of the turbine and generator to electricity, the delivery of electricity through the power grid, and the conversion to motion in motors for use in industry, transportation, and refrigeration can be more than 90 percent efficient. None of these steps produces greenhouse gas emissions. Electricity’s post-production versatility, cleanliness, and efficiency make it a prime energy carrier for the future. Based on relatively plentiful domestic coal and gas, electricity generation is free of immediate fuel security concerns. The advent of electric cars promises to increase electricity demand and reduce dependency on foreign oil, while the growth of renewable wind and solar generation reduces carbon emissions. The primary sustainability challenges for electricity as an energy carrier are at the

production step: efficiency and emission of carbon dioxide and toxins.

The Electricity Grid: Capacity and Reliability

Beyond production, electricity faces challenges of capacity, reliability, and implementing storage and transmission required to accommodate the remoteness and variability of renewables. The largest capacity challenges are in urban areas, where 79 percent of the United States and 50 percent of the world population live. The high population density of urban areas requires a correspondingly high energy and electric power density. In the United States, 33 percent of electric power is used in the top 22 metro areas, and electricity demand is projected to grow 31 percent by 2035. This creates an “urban power bottleneck” where underground cables become saturated, hampering economic growth and the efficiencies of scale in transportation, energy use, and greenhouse gas emission that come with high population density. Saturation of existing cable infrastructure requires the installation of substantial new capacity, an expensive proposition for digging new underground cable tunnels.

The reliability of the electricity grid presents a second challenge. The United States’ grid has grown continuously from its origins in the early 20th Century; much of its infrastructure is based on technology and design philosophy dating from the 1950s and 1960s when the major challenge was extending electrification to new rural and urban areas. Outside urban areas, the grid is mainly above ground, exposing it to weather and temperature extremes that cause most power outages. The response to outages is frustratingly slow and traditional– utilities are often first alerted to outages by telephoned customer complaints, and response requires sending crews to identify and repair the damage, much the same as we did 50 years ago. The United States’ grid reliability is significantly lower than for newer grids in Europe and Japan, where the typical customer experiences ten to 20 times less outage time than in the United States. Reliability is especially important in the digital age when an interruption of even a fraction of a cycle can shut down a digitally controlled data center or fabrication line, requiring hours or days to restart.

Reliability issues can be addressed by implementing a smart grid with two-way communication between utility companies and customers that continuously monitors power delivery and the operational state of the delivery system and implements demand response measures adjusting the power delivered to individual customers in accordance with a previously established unique customer protocol. Such a system requires installing digital sensors that monitor power flows in the delivery system, digital decision and control technology, and digital communication capability like that already standard for communication via the Internet. For customers with on-site solar generation capability, the smart grid would monitor and control the selling of excess power from the customer to the utility.

Integrating Renewable Electricity on the Grid

Accommodating renewable electricity generation by wind and solar plants is among the grid’s most urgent challenges. Leadership in promoting renewable electricity has moved from the federal to the state governments, many of which have legislated Renewable Portfolio Standards (RPS) that require 20 percent of state electricity generation to be renewable by 2020. Thirty states and the District of Columbia have such requirements, the most aggressive being California, with 33 percent renewable electricity required by 2020, and New York, with 30 percent by 2015. To put this legal requirement in perspective, wind and solar now account for about 1.6 percent of U.S. electricity production, approximately a factor of ten short of the RPS requirements. (Crabtree & Misewich, 2010).

Renewable Variability

The grid faces major challenges in accommodating the variability of wind and solar electricity. Without significant storage capacity, the grid must precisely balance generation to demand in real-time. The variability of demand controls the balancing process: demand varies by as much as a factor of two from night to day as people go through their daily routines. This predictable variability is accommodated by switching reserve generation sources in and out in response to demand variations. With renewable generation, variation can be up to 70 percent for solar electricity due to passing clouds and 100 percent for wind due to calm days, much larger than the variability of demand. At the present level of 1.6 percent wind and solar penetration, the relatively small variation in generation can be accommodated by switching in and out conventional resources to make up for wind and solar fluctuations. At the 20 percent penetration required by state Renewable Portfolio Standards, accommodating the variation in generation requires a significant increase in the conventional reserve capacity. At high penetration levels, each addition of wind or solar capacity requires a nearly equal addition of conventional capacity to provide generation when the renewables are quiescent. This double installation to ensure reliability increases the cost of renewable electricity and reduces its effectiveness in lowering greenhouse gas

emissions.

A major complication of renewable variation is its unpredictability. Unlike demand variability, which is reliably high in the afternoon and low at night, renewable generation depends on weather and does not follow any pattern. Anticipating weather-driven wind and solar generation variability requires more sophisticated forecasts with higher accuracy and greater confidence levels than are now available. Because today’s forecasts often miss the actual performance target, additional conventional reserves must be held ready to cover the risk of inaccuracies, adding another increase to the cost of renewable electricity. Storage of renewable electricity offers a viable route to meeting the variable generation challenge.

How to Transmit Electricity Over Long Distances

The final challenge for accommodating renewables is the long-distance transmission. Although long-distance delivery is possible where special high-voltage transmission lines have been located, the capacity and number of such lines are limited. The situation resembles automobile transportation before the interstate highway system was built in the 1950s. It was possible to drive coast to coast, but the driving time was long and uncertain, and the route was indirect. To use renewable electricity resources effectively, we must create a kind of interstate highway system for electricity.